Pet food extruder is suitable to make dry pet food for dog, cat, fish etc. Different sizes and shapes can be made by changing molds. Currently we have different capacity for choice, from 150kg/hr to 5000kg/hr.

| Availability: | |

|---|---|

| PDF Export | |

DR95/120/130

DARIN

84388000

Feature

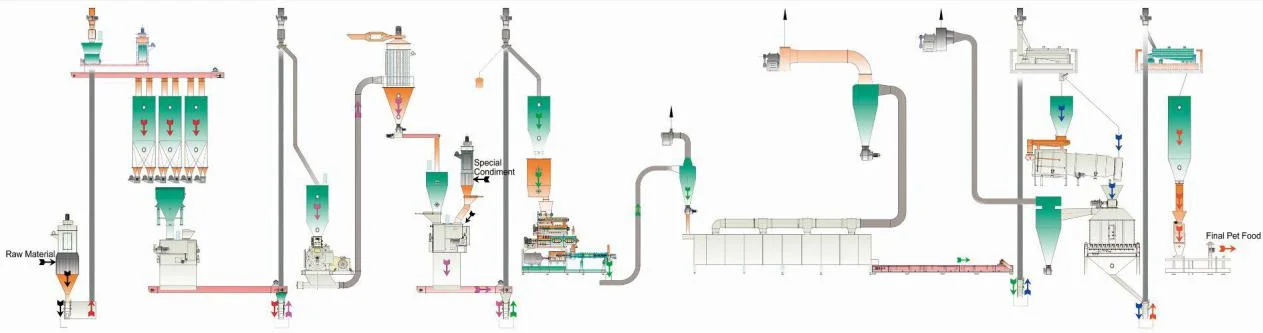

The pet food line is suitable to make dry pet food for dog, cat, fish etc. Different sizes and shapes can be made by changing molds.

The 2-5ton pet food line are large project and usually should be customized as client's real workshop size. Also it has height limit, usually we recommend the mini height be 12m, the higher the better.

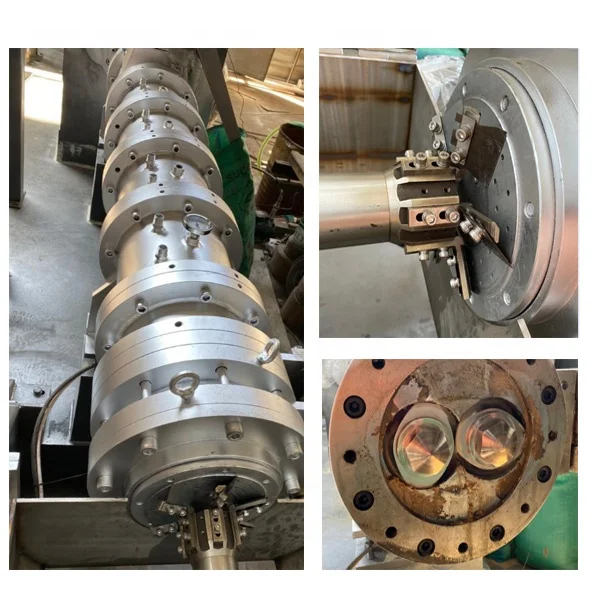

Features of 2-5ton pet food twin screw extruder

1. Advanced electronic control operating system makes it easier to control product quality, all parameters at a glance;

2. Transmission system adopts high precision and high strength gear box transmission, running balance, high transmission efficiency, the main machine is frequency conversion motor.

3. Dual-axis diameter difference conditioning device has the advantages of good conditioning effect. Double screw design high pressure, self-cleaning performance. Mixing blade adjustment is convenient and flexible, keeping time can be selected; Liquid filler is reserved;

4. High precision feeding auger ensures accurate feeding quantity;

5. Wear-resistant bushing is embedded in the barrel and jacket is provided, which can be heated/cooled to facilitate the expansion of the product.

6. Efficient use of energy, reduce energy consumption, reduce processing costs;

7. The expanded granule has good stability in the water, which can effectively protect the breeding water and reduce pollution.

Technical Parameter

Model | Capacity | Power | Dimension |

DR-65 | 120-150kg/h | 80kw | 18*5*3m |

DR-70 | 200-300kg/h | 90kw | 20*5*3m |

DR-85 | 500-600kg/h | 150kw | 30*5*4m |

DR-90 | 800-1000kg/h | 200kw | 35*5*5m |

DR-95 | 2000kg/h | 250kw | 40*10*16m |

DR-120 | 3000kg/h | 350kw | 50*10*20m |

DR-135 | 5000kg/h | 450kw | 60*10*24m |

Product Details

Company Video

FAQ

1. Could we visit your factory to check the machine carefully and closely?

You’re more than welcome to visit Darin, we will provide machine test running, face to face discussioin and turkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commssioning service provided, our technician will help to install the machine, and teach local workers about operation and manitenance. Buyer should pay for the technician’s round flight ticket , accommodation and salary.

3. How long is your machine’s guarantee time?

One year from the machine arrive at your factory.

4. If some parts break after warranty, what should we do?

Darin supply full-life after sales service, whenever new parts needed, we will help to supply new replacments at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

AutoCAD layout will be provided as client’s workshop size.

6. During epedemic period, how should we install the processing line without any experience?

1) Before delivery, we will take detailed operation video to show how to assemble each machine, how to operate and maintain the line.

2) Operation manual, circuit diagram etc in English version will be provided.

3) Online support available. If any questions during installation or production, our engineer will help to solve by videocall or zoom meeting.