Boost your snack business with our Doritos, Tortilla Chips, Nachos, and Corn Chips Production Lines—designed for snack manufacturers, OEM brands, and export-oriented food companies. Produce crispy, perfectly shaped triangular chips with consistent texture and flavor, ready to impress your customers.

Key Advantages:

Flexible Capacity: 100-500 kg/h for small, medium, or large-scale production.

Fully Automated: From mixing and extrusion to frying/baking and cooling—minimal labor required.

Industrial-Grade Components: High-performance extruders and PLC control for stable, long-lasting operation.

Customizable Recipes: Supports corn, rice, wheat flour, and a variety of flavorings for your unique products.

Cost-Effective: High output with low labor and minimal downtime.

Ideal for:

Snack factories producing branded or private-label chips.

OEM / contract manufacturers supplying multiple brands or export markets.

Startups and growing food enterprises aiming for efficient, high-quality production.

With our production lines, you can efficiently produce market-ready, delicious triangular chips that keep customers coming back for more.

| Availability: | |

|---|---|

| PDF Export | |

DRD-65, DRD-75, DRD-85, DRD-95

DARIN

84388000

Features

Our Doritos, Tortilla Chips, Nachos Chips, and Corn Chips Production Line is engineered for commercial snack manufacturers seeking stable quality, scalable capacity, and efficient operation. The line delivers continuous production of uniform, crispy triangular chips, meeting the requirements of both domestic and export markets.

This production line is purpose-built for:

Snack factories producing branded or private-label triangular chips

OEM / contract tortilla chips manufacturers supplying multiple brands

Export-oriented food companies requiring consistent quality and compliance

Its industrial design ensures reliable output, recipe consistency, and long-term operation—key factors for competitive snack production.

At the heart of the system is a high-efficiency Doritos / Tortilla Chips Extruder, ensuring:

Accurate dough forming and stable triangular shapes

Uniform thickness and texture across each batch

Smooth, continuous extrusion without production interruptions

This guarantees consistent chip appearance and crunch, essential for brand recognition.

The line supports both fried and baked corn chips processing, allowing manufacturers to adapt to different market trends:

Fried tortilla chips for traditional crunch and rich flavor

Baked corn chips for reduced oil content and healthier positioning

This flexibility helps brands quickly respond to regional preferences and consumer demand.

Our Corn Chips Processing Line works with a wide range of raw materials, including:

Corn flour, rice flour, wheat flour

Customized seasoning powders and flavor systems

Manufacturers can easily adjust formulas to develop unique tastes, textures, and product positioning for different markets.

Designed for modern snack factories, the line features:

PLC-controlled automation from mixing to cooling

Reduced labor requirements and stable production rhythm

High output with minimal downtime

This results in lower operating costs and improved production efficiency.

Built with industrial-grade components, the production line offers:

Stable, long service life

Easy operation and maintenance

Capability for future capacity expansion

It is a reliable solution for businesses planning long-term growth in the global snack industry.

With a capacity range from 500 kg/h to 5 t/h, this Triangular Chips Production Line supports:

Startups entering the snack market

Medium-sized factories expanding output

Large-scale producers serving multiple markets

The modular design allows smooth upgrades as production demand increases.

This Tortilla Chips Production Line follows a mature, industrial process designed for stable output, consistent product quality, and efficient large-scale production.

Flow Chart:

Mixing → Extrusion & Forming → Frying / Baking → Seasoning → Cooling & Packing.

Corn flour, rice flour, wheat flour, and water are accurately proportioned and mixed to form a uniform dough. Stable mixing is critical to ensure smooth extrusion and consistent chip texture during continuous production.

The mixed dough is fed into a high-performance tortilla chips extruder, where it is thermally processed and plasticized. Precise control of temperature and screw speed ensures proper starch gelatinization and stable dough structure.

The cooked dough sheet is shaped and cut into uniform triangular chips with consistent thickness and clean edges. This forming process ensures visual consistency and reliable downstream processing.

Depending on product requirements, the formed chips pass through either:

Frying systems for traditional crunchy tortilla chips

Baking ovens for reduced-oil or healthier snack products

Both processes deliver even heat distribution, consistent color, and controlled moisture levels.

After thermal processing, chips enter an automatic seasoning system where oil and flavor powders are evenly applied. This guarantees uniform taste, strong flavor adhesion, and batch-to-batch consistency.

The finished chips are gradually cooled to stabilize texture, reduce breakage, and prepare the product for packaging. Controlled cooling improves shelf stability and final product quality.

The entire tortilla chips production line is PLC-controlled, enabling continuous operation with minimal labor input. Automated monitoring ensures stable output and reduced downtime.

Darin focuses on reliability, safety, and long-term performance. Every key component is carefully selected to ensure stable operation, easy maintenance, and consistent product quality.

Motors are from Siemens, ensuring strong driving force, stable operation, and extended machine lifespan, even under long-time continuous production.

Electric parts are from ABB or Schneider, internationally recognized brands.

Easy to find replacements in the local market, reducing downtime and maintenance costs.

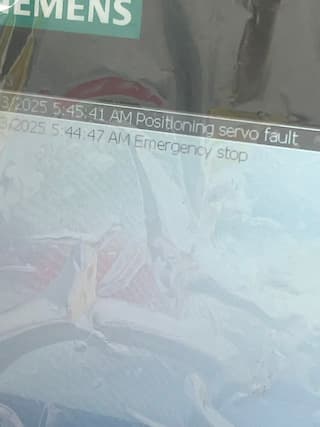

PLC and touch screen are from Siemens, providing intuitive operation and reducing labor requirements.

Operators can control the entire line easily with minimal training.

The PLC and touch screen control the whole processing line, not just one or two individual machines.

This ensures better coordination, higher efficiency, and smoother production flow.

When a fault occurs, relevant information is displayed directly on the touch screen, allowing operators to identify and solve problems quickly, without checking machines one by one.

The control cabinet uses 24V safe voltage (not 220V), which effectively protects operators, even in case of electrical leakage.

Three kinds of protectors ensure maximum safety for both machine and operator:

Over-current protection

Over-voltage protection

Over-heat protection

This multi-layer protection guarantees safe and reliable long-term operation.

All cover bodies, mesh belts, and parts in contact with raw materials or final products are made of Stainless Steel 304, meeting food-grade standards and ensuring hygiene, corrosion resistance, and easy cleaning.

With world-famous components, advanced control systems, and strict safety design, Darin machines are trusted by customers worldwide for stable performance, easy maintenance, and long-term value.

Technical Parameter

Item | Brand |

Motor | Siemens |

Electric Parts | Siemens or Schneider |

PLC and Touch Screen | Siemens |

Materials | Cover body, mesh belt and parts touching with raw materials or final products are stainless steel |

Product Details

About Darin

FAQ

1. Could we visit your factory to check the machine carefully and closely?

You’re more than welcome to visit Darin, we will provide machine test running, face to face discussioin and turkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commssioning service provided, our technician will help to install the machine, and teach local workers about operation and manitenance. Buyer should pay for the technician’s round flight ticket , accommodation and salary.

3. How long is your machine’s guarantee time?

One year from the machine arrive at your factory.

4. If some parts break after warranty, what should we do?

Darin supply full-life after sales service, whenever new parts needed, we will help to supply new replacments at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

AutoCAD layout will be provided as client’s workshop size.

6. During epedemic period, how should we install the processing line without any experience?

1) Before delivery, we will take detailed operation video to show how to assemble each machine, how to operate and maintain the line.

2) Operation manual, circuit diagram etc in English version will be provided.

3) Online support available. If any questions during installation or production, our engineer will help to solve by videocall or zoom meeting.