Application

Produce high-quality floating and sinking fish feed for various species. Ensures stable floating, uniform nutrition, and consistent pellet quality. Ideal for commercial aquaculture and industrial feed production.

Process

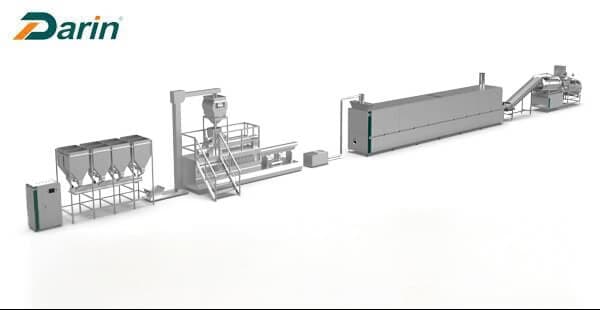

Mixing → Screw Conveying → Extruding → Sifting → Air Conveying → Drying → Flavoring → Packaging.

Fully automatic, continuous, and high-capacity, reducing labor and downtime.

Raw Materials

Corn flour, rice flour, wheat flour, fish bone meal, chicken powder, glycerol, etc. Flexible formulas for cost and nutrition adjustment.

Key Features

Siemens motor & PLC for stable, long-lasting operation

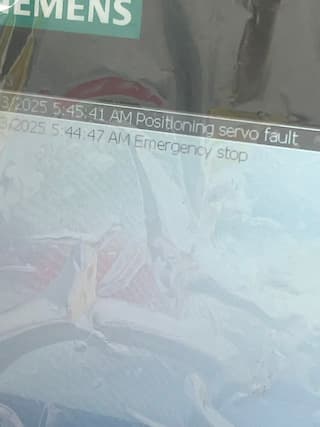

Touch screen control & real-time fault display

Low labor cost, high efficiency

Customizable voltage

Capacity & Price

1–10 t/h, suitable for medium to large feed factories.

USD 60,000 – 300,000, depending on configuration and automation.

Ideal For

Large fish feed manufacturers

Commercial aquaculture farms

Start-ups with scalable capacity

OEM / private label producers

Integrated aquaculture enterprises

| Availability: | |

|---|---|

| PDF Export | |

DR-90, DRF-95, DRF-120, DR-135

DARIN

84388000

Product Details

Flow Chart

Floating Fish Feed Processing Line focuses on the production of feeds for animals with a high emotional value but low economic usefulness, apart from the aspect of breeding. Nonetheless, balancing the components and gentle processing are at the center of the related quality considerations. Extrusion is therefore increasingly proving to be the right tool for modern Pet food. A complete feed, fed as a diet over a prolonged period of time, must ensure the vitality of the animal and prevent deficiencies. This is quite a challenge to the feed manufacturer in terms of the selection and composition of the raw materials, their optimal processing, and effective quality assurance. A large number of pet food products are made by extrusion.

1) Dog and cat foods, directly extruded and dried, dry or semi-moist. These constitute the biggest market segment.

2)Feed for fish, high-grade complete feeds capable of maintaining the health even of exotic species in aquariums over prolonged periods of time, sinking or floating feed.

Darin focuses on reliability, safety, and long-term performance. Every key component is carefully selected to ensure stable operation, easy maintenance, and consistent product quality.

Motors are from Siemens, ensuring strong driving force, stable operation, and extended machine lifespan, even under long-time continuous production.

Electric parts are from ABB or Schneider, internationally recognized brands.

Easy to find replacements in the local market, reducing downtime and maintenance costs.

PLC and touch screen are from Siemens, providing intuitive operation and reducing labor requirements.

Operators can control the entire line easily with minimal training.

The PLC and touch screen control the whole processing line, not just one or two individual machines.

This ensures better coordination, higher efficiency, and smoother production flow.

When a fault occurs, relevant information is displayed directly on the touch screen, allowing operators to identify and solve problems quickly, without checking machines one by one.

The control cabinet uses 24V safe voltage (not 220V), which effectively protects operators, even in case of electrical leakage.

Three kinds of protectors ensure maximum safety for both machine and operator:

Over-current protection

Over-voltage protection

Over-heat protection

This multi-layer protection guarantees safe and reliable long-term operation.

All cover bodies, mesh belts, and parts in contact with raw materials or final products are made of Stainless Steel 304, meeting food-grade standards and ensuring hygiene, corrosion resistance, and easy cleaning.

With world-famous components, advanced control systems, and strict safety design, Darin machines are trusted by customers worldwide for stable performance, easy maintenance, and long-term value.

Flour mixer-screw conveyor-twin screw extruder-sifter-air conveyor-roaster-small hoister-flavoring machine

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

Fast professional consultation for your feed project

Customized line solution based on capacity, raw materials, and budget

Free sample testing to verify feed quality before purchase

Formula & process guidance to ensure stable extrusion results

Production layout & cost estimation for quick decision-making

Factory visit or live video inspection available anytime

Contact us now for a customized solution and quotation.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Professional installation & operation training

Step-by-step guidance to ensure smooth installation and fast production start-up.

Overseas engineer support available

Experienced engineers can provide on-site service when required.

Online technical support

Fast response via video call, email, or messaging to solve issues quickly.

Clear manuals & training materials

Easy-to-follow documents for daily operation and maintenance.

Long-term technical assistance

Continuous support to keep your line running efficiently and reliably.

We support you from installation to stable production.

Technical Parameter

Model | Capacity | Power | Dimension |

DR-90 | 800-1000kg/h | 200kw | 35*5*5m |

DR-95 | 2000kg/h | 250kw | 40*10*16m |

DR-120 | 3000kg/h | 350kw | 50*10*20m |

DR-135 | 5000kg/h | 450kw | 60*10*24m |

Company Video

FAQ

1. Could we visit your factory to check the machine carefully and closely?

You’re more than welcome to visit Darin, we will provide machine test running, face to face discussioin and turkey project design solution.

2. Could you afford technician team to guide our installation and commissioning?

Oversea commssioning service provided, our technician will help to install the machine, and teach local workers about operation and manitenance. Buyer should pay for the technician’s round flight ticket , accommodation and salary.

3. How long is your machine’s guarantee time?

One year from the machine arrive at your factory.

4. If some parts break after warranty, what should we do?

Darin supply full-life after sales service, whenever new parts needed, we will help to supply new replacments at reasonable price & in shortest time.

5. If we show our workshop size, can you design layout for the whole line?

AutoCAD layout will be provided as client’s workshop size.

6. During epedemic period, how should we install the processing line without any experience?

1) Before delivery, we will take detailed operation video to show how to assemble each machine, how to operate and maintain the line.

2) Operation manual, circuit diagram etc in English version will be provided.

3) Online support available. If any questions during installation or production, our engineer will help to solve by videocall or zoom meeting.